Subsea technology company Seatools has achieved a significant milestone by delivering deep-sea mineral collection equipment for Allseas’ innovative seabed mining ship, the Hidden Gem. This delivery marks a pivotal advancement in the exploration and extraction of polymetallic nodules from the ocean floor, which are rich in essential metals for the burgeoning electric vehicle and renewable energy sectors.

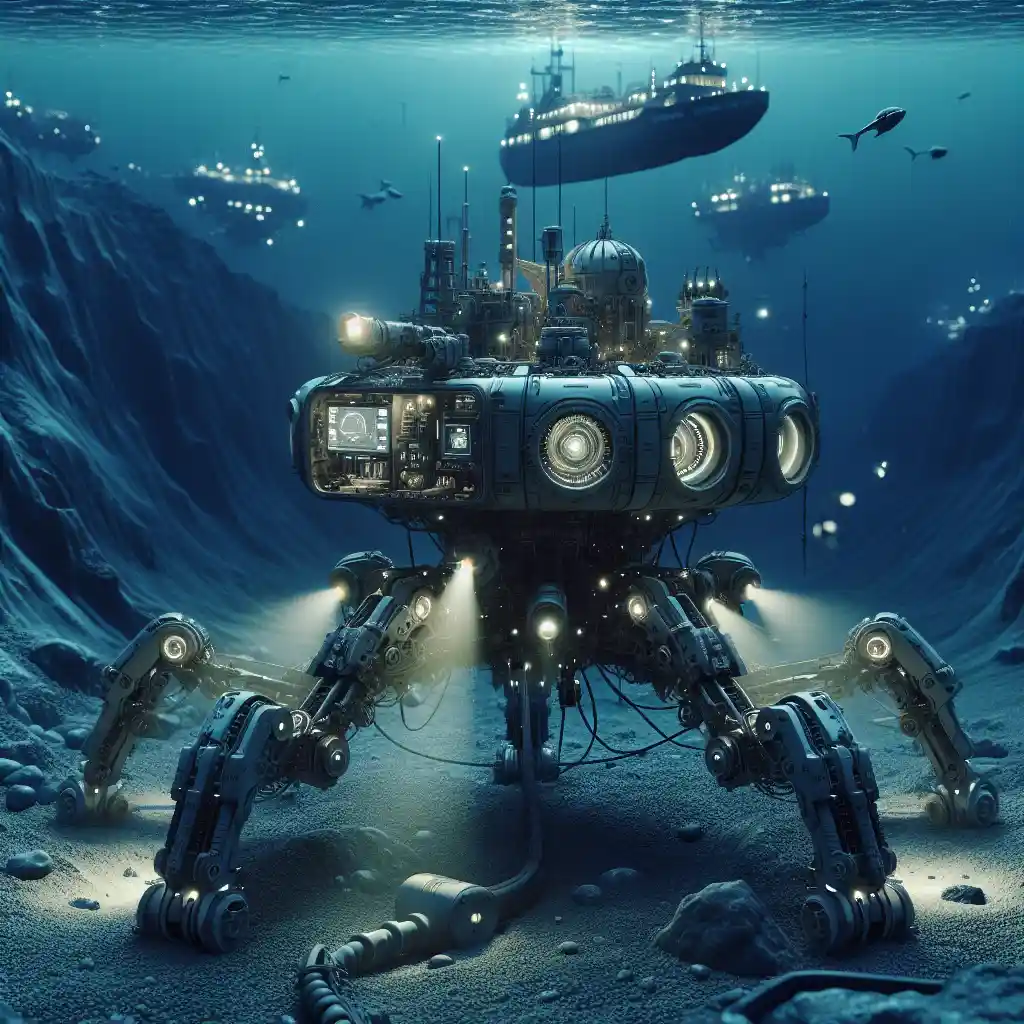

Seatools’ role encompassed the comprehensive engineering, manufacturing, and qualification of critical systems including electronics, instrumentation, and hydraulics for Allseas’ pilot polymetallic nodule collection vehicle. This vehicle is a cornerstone of a pilot nodule collection test set to be conducted by Allseas in 2022 in the Pacific Ocean, aiming to validate the feasibility and efficiency of deep-sea mineral collection at unprecedented depths.

Allseas engineered and produced the core nodule collection technology and the mechanical assembly for the 70+ tons tracked subsea vehicle internally. Seatools brought this nodule collector to life by providing the complete hydraulic, electronic, and control system. The project involved an extensive development trajectory, including design, construction, qualification, and testing phases, showcasing Seatools’ capability in handling complex, high-tech solutions for deep-water operations.

Rutger Bosland, Project Manager Polymetallic Nodule Collection at Allseas, highlighted the completion of the hydraulic, electronic, and control system as a major milestone in preparing for their pilot mineral collection operations. He emphasized the project’s complexity and the challenges it posed, which Seatools met by delivering a solution capable of operating at depths up to 5000 meters.

Jan Frumau, Managing Director at Seatools, expressed honor in playing a significant role in this pioneering project. He pointed out that the rigorous engineering approach adopted by Seatools resulted in delivering technology of space quality levels, equipping Allseas with state-of-the-art remotely operated vehicle (ROV) and subsea technology. This underscores Seatools’ multidisciplinary engineering approach and its strength in providing high-end, mission-critical subsea equipment for leading offshore contractors like Allseas.

The project is part of an industry-first initiative, with the conversion of Allseas’ 228-meter drillship Vitoria 10000, now renamed Hidden Gem, into a subsea mining vessel. This vessel is equipped with a deep-sea mineral collection system designed to recover polymetallic nodules from the ocean floor and transfer them to the surface. These nodules contain high grades of nickel, manganese, copper, and cobalt—essential for manufacturing electric vehicle batteries and renewable energy technologies. The vessel’s conversion process began in Rotterdam in September, with the Hidden Gem set to become the first vessel to be classed as a subsea mining vessel by the classification society ABS.

This collaboration between Seatools and Allseas represents a significant leap forward in the sustainable extraction of deep-sea minerals, potentially revolutionizing the supply of critical metals necessary for the future of energy and transportation technologies.